- Home

- Labeler Series

- Horizontal Labeler-Cylindrical Bottles Series

- Horizontal Ampoule Labeler with Automatic Bottle and Tray Input Devices

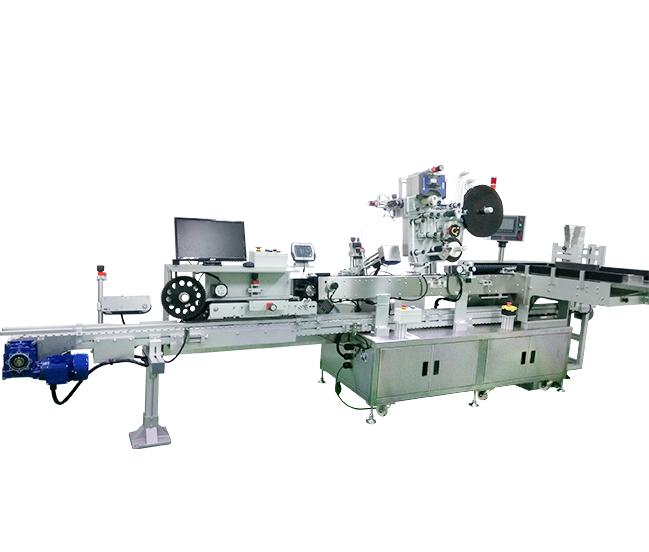

Horizontal Ampoule Labeler with Automatic Bottle and Tray Input Devices

Suitable for labeling full or half round on ampoule bottles, syringe bottles, essence bottles, and oral liquid bottles. Roller conveyor ensure stable high speed labeling and no bottle breaking.

Features

- Automatic trays inserting can greatly increase production speed, reduce manpower of production lines, and save production costs.

- Can be connected to the previous vertical turn table, the stability of horizontal labeling to facilitate high-speed operation.

- he stacking flat-push type feeding mechanism is matched with a two-stage differential tray conveyor, which effectively reduces the waiting time for empty trays and ensures continuous production smoothly.

- Driven by the labeler and wrap around device enable stable and precise synchronization of multiple mechanisms.

- Standardized and modular design for easy maintenance.

- Color touch panel and PLC control system. Easy to learn and operate.

Optional Accessories

- Compatible with CCD inspection system

- Defect rejecting system

- Input/output turntable.

- Various printer options (hot stamping, inkjet printer, thermal transfer printer, laser printers)

- Available for connecting with filler for labeling as in-line or stand-alone labeling as off-line.

Production Solution

Specification

| Model | Horizontal Ampoule Labeler with Automatic Bottle and Tray Input Devices |

| Labeler Line Speed | 30 to 50 m/min |

| Labeling Speed | About 150 Bottle/min |

| Accuracy | ±1mm |

| Label Width | S(50mm)/ M(100mm) / L(140mm) |

| Object Size | Under 60mm |

| Label Roll | 300/400mm |

| Machine Dimension | 2500mm(L) × 1200mm(W) × 1550mm(H) |

| Machine Weight | 300kg |

| Power | AC 220V 50/60Hz Single Phase; 2kW |

Production capacity is for reference only. It'll change according to different product specifications.

Application Areas

Pharmaceutical and Biotechnology Industry

Labeling machine recommendation & comparison